Rebuilding Rönnskär

Foundation work under harsh conditions

In the early hours of June 13, 2023, the small coastal town of Skelleftehamn in northern Sweden was shaken awake by sirens and smoke. A fire had broken out at Boliden’s Rönnskär smelter – Sweden’s only facility for producing base metals and recycling electronic scrap. The electrolysis plant, at the heart of the operation, was devastated. Production halted. Hundreds of jobs were at stake.

Boliden acted quickly. Within months, the company announced a SEK 4.8 billion investment to rebuild the electrolysis facility on the same site, with the goal of making it operational again by 2026. NCC, one of the leading construction companies in the Nordics, was selected as the main contractor, and Hercules, a specialist in foundation engineering and part of the NCC Group, was assigned to handle one of the most critical and complex aspects of the rebuild: the ground foundation work.

That challenge was far from straightforward. The ground beneath the plant was filled with construction debris dating back to the mid-20th century, and it was heavily contaminated with lead, cadmium, arsenic, and copper slag.

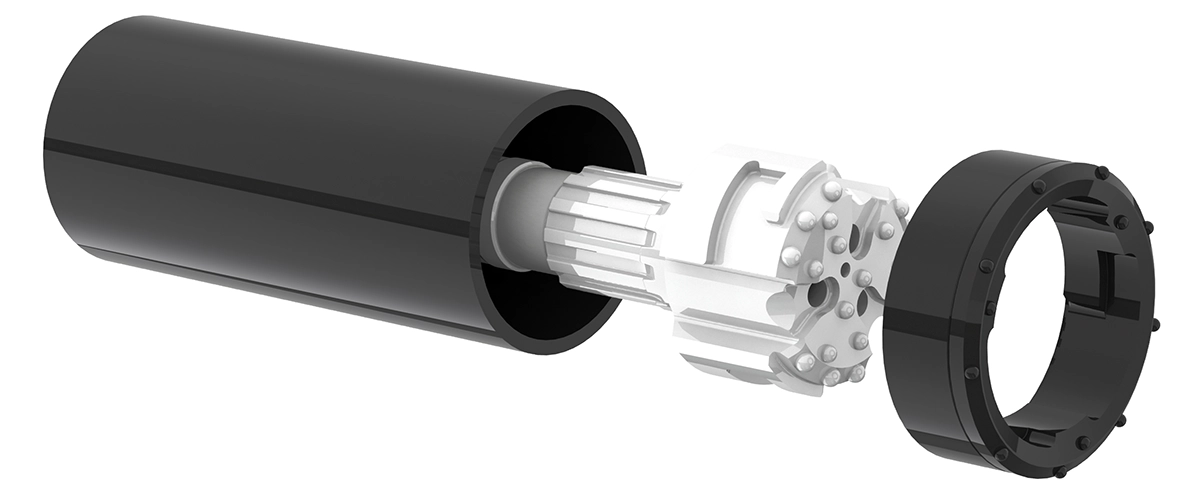

This required special protective measures for the structures and the individuals performing the work. The steel piles had to be corrosion-protected using six-metre-long casing pipes, ensuring durability in the toxic soil. Meanwhile, site crews operated under strict safety protocols, requiring a higher-than-normal level of personal protective equipment throughout the piling phase. Add to that a massive scale: nearly 3,000 piles were drilled, totaling 90,000 meters, under a highly compressed timeline.

For this demanding job, Hercules relied on Robit, their long-time partner.

First, Robit’s DTH Prime ring bits were used to drill 323 mm protective casings to prevent the pipe piles from corrosion in the contaminated soil. 168 mm piles were then drilled through the protective casings. Robit’s pilot bits, also from the DTH Prime range, played a central role in the process.

“Hercules Site Managers Robert Kangasmaa and Jonas Hedlund have reported that the tools performed extremely well in the challenging conditions. Hercules, our long-standing customer, was very satisfied with their performance,” says Ville Pohja, VP Geotechnical at Robit.

While Robit and Hercules have collaborated on numerous projects over the years, this was by far their largest effort to date.

“In piling, a large project typically involves a few hundred piles – this one had almost 3,000. We were proud to be able to supply such a large number of ring bits on short notice and at a rapid pace,” Pohja adds.

The piling phase, which ran from May to December 2024, was executed with precision and speed. Double-shift drilling operations ran for up to 19 hours daily, with more than 70 people involved at the project’s peak.

With the foundation work now completed, the new electrolysis plant is rising – a symbol of resilience and renewal. Once operational in 2026, it will not only restore vital production capacity for Boliden but also bring new employment opportunities and long-term benefits to the Skelleftehamn region.