5.4.2022 | Sustainability at Robit

Robit’s promise to be Your partner for a more sustainable tomorrow

Sustainability as a topic has been present in business for a long time already, however, it has been gaining more and more traction and attention in recent years. This has caused many companies, including Robit, to re-orient themselves, in order to bring sustainability-related matters more into focus. At Robit, this is done by committing to new sustainability KPIs (Key Performance Indicators) and asking the company’s stakeholders to do the same. Robit has always had sustainable practices, like sourcing materials from responsible partners, as well as setting a high priority to employees’ health and safety. Recently, however, the company has been in the process of doubling down on its sustainability efforts and setting clear objectives for these practices, based on a common vision created through extensive cooperation between the management and the employees. With the launch of the ESG (Environment, Social, Governance) roadmap in September 2021, the ESG practices of the company have been refined and further defined.

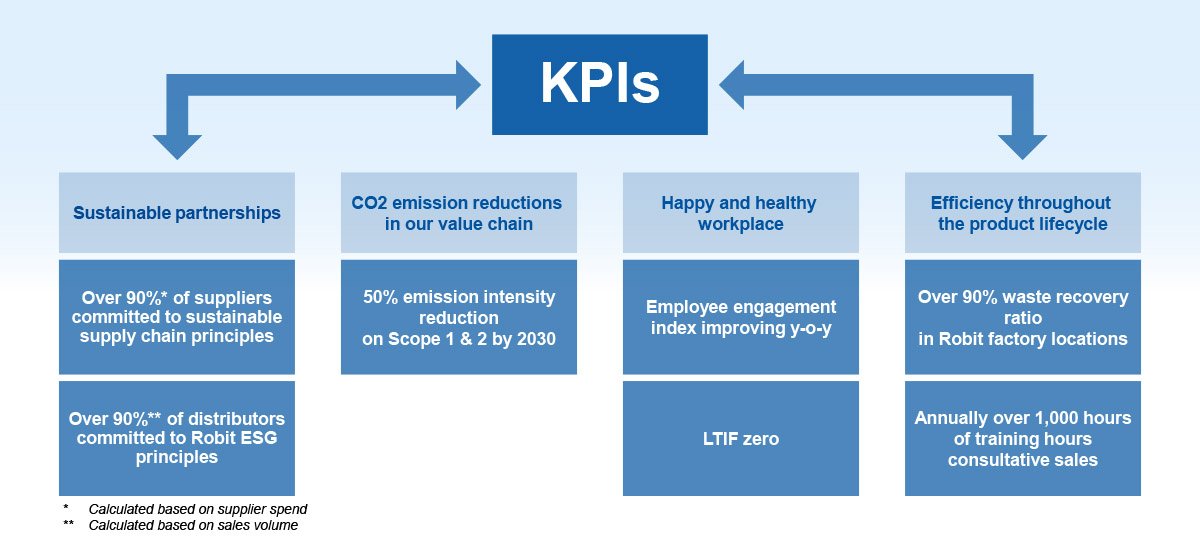

As a result, Robit’s actions have been divided into four key areas:

- Sustainable partnerships: Robit works with partners that share and respect its ESG principles and aims.

- CO2 emission reduction in the value chain: Robit not only cuts the CO2 emissions caused by its own operations, but also strives to influence emissions’ reductions at its external stakeholders.

- Healthy and happy workplace: Robit maintains a desired work environment by ensuring the safety of its employees and continuing to build diversity and inclusion as central and empowering parts of the company culture.

- Efficiency throughout product lifecycle: Robit treats its materials with respect, increasing efficiency and reducing waste in its own and its customers’ operations, while also lengthening product lifetime through training and value adding services.

The aim of these four pillars is to tackle sustainability issues from several directions at once. This creates a holistic approach that extensively addresses different areas of the business, which Robit will use to establish itself as a company tackling important issues in innovative ways. Furthermore, they are already ingrained in Robit’s culture and working practices, thus benefitting the company’s day-to-day operations.

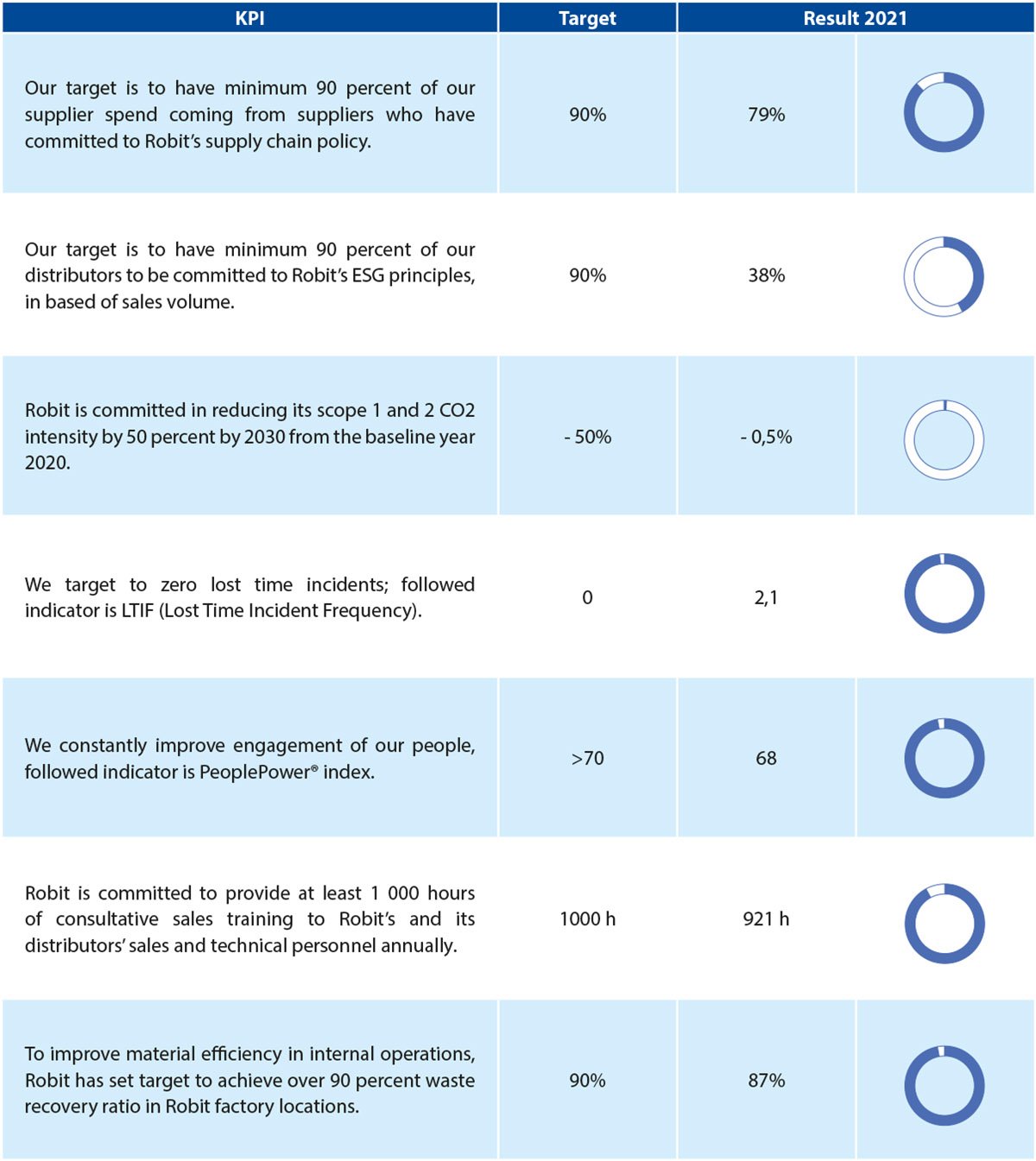

Even though the concrete KPIs for the above key areas were launched only last September, there are already several actions taken and some significant results that have been reached.

- Robit targets to have a minimum of 90 percent of its supplier spend coming from suppliers who have committed to Robit’s supply chain policy. The result at the end of 2021 was already at 79 percent.

- A first step towards CO2 emission reduction was taken by building a calculation tool to recognize Scope 1 and 2 CO2 emissions caused by Robit’s own operations. The company will also increase the share of green energy in its factories, with the first changes having been implemented at its Australian factory in October 2021.

- For a healthy and happy workplace, the KPI is to target zero lost time incidents, based on LTIF (Lost Time Incident Frequency). In 2021 the result was 2,1, which is already a significant improvement from 4,2 in 2020. In January 2022, Robit reached LTIF of 0,0.

- To increase efficiency throughout product lifecycle, Robit has set a KPI of providing at least 1 000 hours of consultative sales training annually to the sales and technical personnel of the company and its distributors. Additionally, Robit has set the target to achieve over 90 percent waste recovery ratio in its factory locations. The 2021 results for these were 921 hours and 87 percent, respectively, bringing the company very close to reaching these milestones.

Keep checking back with Robit to learn more!