Far North Queensland (FNQ) is one of the fastest-growing regions in Australia. Despite being the region with the most annual rainfall in the country, FNQ is facing water supply challenges. Particularly along the coast, the area’s capacity to store water for urban use is limited, which may hinder future growth. Some parts of FNQ have even seen water outages in recent years. As a result, water well drilling has proven to be a vital service for households, industries, and farms in many parts of FNQ.

One of the leading companies providing water well drilling services, as well as bore drilling and utility drilling, in the region is FNQ Drilling, a family-owned business headquartered in Bamboo. Their water well drilling service includes site evaluation, well construction, and pump installation.

In a competitive industry such as well drilling, companies must find ways to improve efficiency or reduce costs to maintain a competitive edge. Shane Naude, the owner of FNQ Drilling, switched to Robit drilling tools a few years ago.

“I was using a hammer that kept breaking barrels and shanking bits without resolution. So I asked around other water well drillers and was told to try Robit. I started using Robit in early 2023 with a D45 DHD340 hammer, a D65W HD QL60 hammer, and bits to suit,” Shane reminisces.

In September 2024, Shane got an opportunity to test and validate the performance and reliability of Robit’s new 6″ H Series hammer in water well drilling. The H Series hammer line was more widely introduced to the Australian market at the DRILL24 trade fair in Perth the following month.

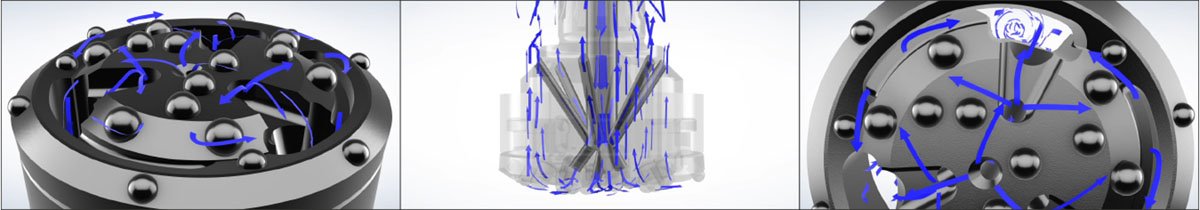

A key selling point of the H Series is its modular design, allowing it to adapt to varying practical needs in the field.

“I do water well drilling in and around all FNQ for domestic, rural, and commercial clients. Ground conditions vary greatly, including shale, basalt, granite, marble, clay, and schist. So, a lot of variation in the hammer performance is needed to suit the ground,” Shane explains.

Shane’s business depends heavily on the quality of his tools. “A reliable hammer is key to my success. More drilling and less downtime due to the product not performing to specifications cost my business money and clients. Due to the remote locations I have clients at, such as stations, I require reliable and suitable products to complete my work.”

“Before switching to Robit, I had many issues with failures, e.g., a simple hammer spring continually failing and causing downtime, costing my Company money and time, and a potential loss of reputation to my business,” Shane says.

After months of validation trials, Shane’s experiences with the new Robit H Series hammer are overwhelmingly positive.

“The trial hammer has drilled approximately 500m of water bore drilling only. All components, including the hammer barrel, piston, top sub, and threads, wear better than those of competitor products previously used.”

“I’m achieving more drilled metres per day. The penetration of the hammer is powerful and punchy, which decreases the time needed to drill a hole. I have also noticed a reduction in my fuel consumption,” Shane says.

In product development, Robit has consistently relied heavily on direct customer experiences and collaboration. The H Series hammer is no exception. Throughout the trials, Shane has discussed with Robit and provided valuable feedback to further improve the hammer’s performance, always with an eye toward that competitive edge.