POSITION AND MAIN RESPONSIBILITIES AT ROBIT

My role is VP Global Sales & Marketing and as implied I am responsible for growing the Robit Group sales across the world. We have recently re-organized our company structure to have stronger focus on driving our growth in selected key areas. In parallel, three (3) distinct Strategic Business Areas have been created to develop each product line’s competitiveness, growth, and profitability; these are Top Hammer, Down the Hole and Geotechnical.

We also need to make sure that we do portray a solid, consistent, and professional image to the outside world therefore our marketing activities are coordinated accordingly.

EXPERIENCE ON THE FIELD

My experience on the field spans some 20 years. Started working with Atlas Copco in Greece as a Business Manager for the Construction & Mining Technique business area back in 2001. Moved to Ghana, West Africa in 2006 at the General Manager of the operation. A very interesting and minerals rich region where mining is the focus. We expanded the business well as we started companies and subsidiaries in Nigeria, Mali, Burkina Faso, Senegal and Cameroun. In 2014, the Central Asian challenge was next. Based in Kazakhstan with a six (6) countries responsibility, we managed to ‘weather’ the recession at the time and started growing the business significantly again by gaining market share.

KEY MARKET TRENDS ON THE FIELD FOR THE NEXT FEW YEARS

The ongoing pandemic has developed the markets to be more volatile than usual and I believe this will be the new norm. This means we should as a Group be extremely pro-active and agile. The mining business is more stable and resilient as we seem to be in another metals prices super-cycle however construction looks ‘slow’ now. There are opportunities in both sectors, and we must be close to benefit the most we could.

HOW DO ROBIT’S ONGOING ACTIONS SUPPORT THE CUSTOMERS AND THEIR CURRENT CHALLENGES?

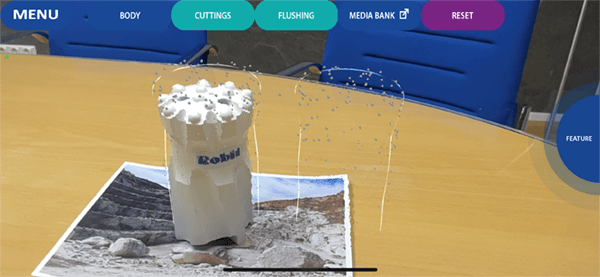

Robit tries to stay as close as possible to our distributors and eventually the end users of our products. We support with product and application training, we conduct product trials and prove our worth on the field, respond quickly to filed issues and ensure that our products do get the deserved recognition in the market.

Our distributors across the world are the key for us and we want to have the best distributor management concept in the market; this would ensure continuous support for them and their customers.

HOW DO YOU SEE ROBIT IN 2021 – WHAT ARE YOUR MAIN EXPECTATIONS ON YOUR FIELD?

We take advantage of the current, limited travel opportunity and fine tune our re-organized sales structure. In other words, we are getting ready for the time that the pandemic eases or is over so that we can again travel and be close to our distributors, partners, and end users for the necessary support.

Our strategy is based on growth, we are a growth company, and this is our main expectation. We want to grow our dealer network and together with them gain market share account by account, a simple and proven method.

For more information: George Apostolopoulos, firstname.lastname@robitgroup.com

Read more Robit ProTALK interviews:

- Jorge Leal, VP Top Hammer

- Adam Baker, VP Down The Hole

- Kari Alenius, VP Finland

- Ville Pohja, VP Geotechnical

- Mikko Vuojolainen, VP North America

- Franco van Deventer, MD Southern Africa

- José Cisneros, MD Robit S.A.C.

- Steve Landreth, VP Australasia

- SK Back, Regional Sales Director – Asia

- Pavel Timofeev, VP CIS & East Europe