Robit Group and BIA Group have signed an exclusive distributor agreement. Based on the agreement, BIA will represent Robit and distribute all Robit products in 17 countries across West and Central Africa (Senegal, Mali, Burkina Faso, Democratic Republic of Congo (DRC), Zambia, Mauritania, Guinea Conakry, Sierra Leone, Liberia, Ivory Coast, Togo, Benin, Niger, Chad, Cameroon, Central African Republic, and Republic of Congo).

Robit’s partnership with BIA is developed to ensure highest possible services levels for drillers in West and Middle African countries.

Tommi Lehtonen, CEO of Robit Group: “We are excited to start this partnership to serve our African drilling consumables customers. Combination of BIA’s strong presence and experienced team together with Robit’s high performance drilling consumables and technical support will offer African customers a strong solution for their drilling consumables needs.”

Vincent Bia, CEO of BIA Group: “Through this new partnership BIA will strengthen its presence in the mining, quarry and construction sectors. BIA’s exposure and knowledge in African market as well as Robit’s wide offering and quality products create an excellent opportunity for both companies to strive for being a major player in the market. With trust, shared values, and common success stories, we are delighted to start our long-lasting partnership with Robit.”

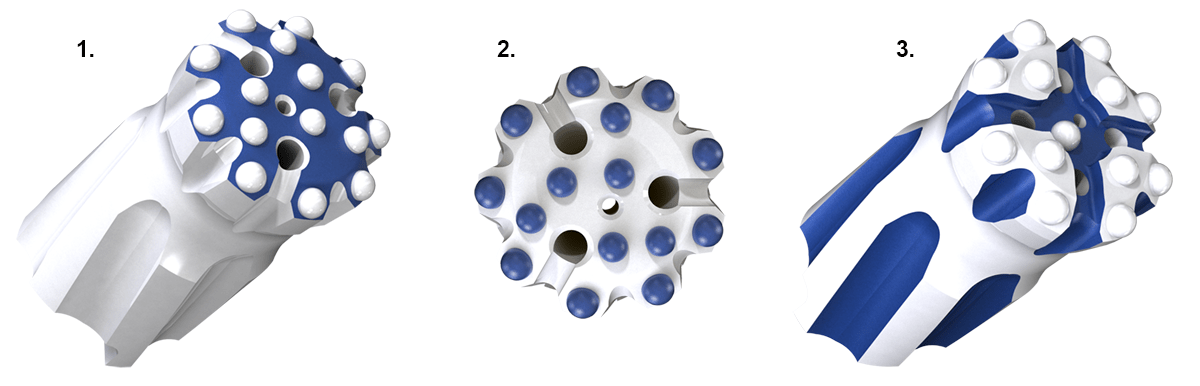

Robit is a strongly internationalized growth company servicing global customers and selling drilling consumables for applications in mining, construction and contracting, tunneling and well drilling. The company’s offering is divided into two product and service ranges: Top Hammer and Down-the-Hole. Robit has 9 of its own sales and service points throughout the world as well as an active sales network in 100 countries. Robit’s manufacturing units are located in Finland, South Korea, Australia and the UK. Robit’s shares are listed on Nasdaq Helsinki Ltd. Further information is available at robitgroup.com.

Since over a century, BIA is recognized by its customers for its expertise in the mining, construction, transport and energy sectors. With a direct presence in more than 20 countries across Europe and Africa and thanks to its 1000 employees, driven by passion, BIA delivers the best equipment, services & technologies to increase customers‘ productivity, improve safety and reduce environmental impact (BIA mission). Further information is available at biagroup.com.

For more information, contact:

Tommi Lehtonen, Group CEO, Robit Group, tommi.lehtonen@robitgroup.com

Aymeric Manteca, Group Marketing Manager, BIA Group, aymeric.manteca@biagroup.com

ROBIT PLC

Tommi Lehtonen

Further information:

Robit Plc

Tommi Lehtonen, Group CEO

+358 40 724 9143

tommi.lehtonen@robitgroup.com

Picture, from left: Tommi Lehtonen (CEO, Robit Group), Kari Alenius (VP EMEA, Robit Group), Vincent Bia (CEO, BIA Group), Alain Vandenplas (General Manager ESB and ACCB, BIA Africa), Eric Perben (General Manager, BIA Africa), Jorge Leal (Director of Global Sales, Robit Group) and Rasmus Sokura (Sales & Distributor Business Manager, Robit Group).