Wolfe Island sits at the north-eastern end of Lake Ontario, at the entrance to the Saint Lawrence River. The Canada–US border runs immediately to the south of the island, leaving it on the Canadian side. A ferry connects the island to the city of Kingston, Ontario.

A popular destination for nature lovers, Wolfe Island’s resident population tends to double or triple in the summer. For years, the ferry has been running near or even over capacity during the busy seasons. That’s why the Ontario Ministry of Transportation launched a major improvement project in 2020. Its goal is to replace the old ferry with a new, larger one, which requires significant upgrades at both ends of the ferry line: Kingston Dock on the mainland and Marysville Dock on Wolfe Island.

The General Contractor for the Marysville Dock project is Facca Inc. from Lakeshore, Ontario. A family business now in the fourth generation, Facca has built a reputation as one of the premier civil construction contractors in Ontario over several decades. They perform all the foundation work, and most of all other work on the Marysville Dock project with their own forces.

“We have been doing our own deep foundation work – piled foundations and sheet piling, some drilled shafts in earth – for about 15 years now. However, this job is only the second for which we’ve performed hard rock drilling of this scope, and the first we’ve done completely with our own forces”, says P.Eng. Steven Gardonio of Facca.

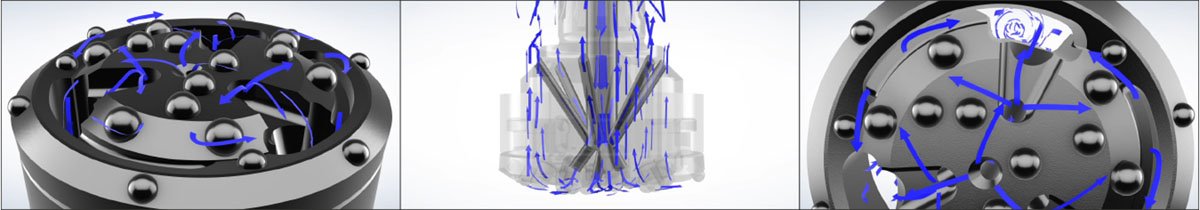

On their Down the Hole hammers for the project, Facca has used both the Robit DTH Prime system and the Robit Steel Fist system, supplied by Pinnacle, Robit´s Canadian distributor. Through their extensive piling expertise, Pinnacle’s Mitch Yorston and Jim McPhail have also provided valuable technical support for Facca.

“We’re putting in about 1,800 m of caisson with the Primes through a mixture of clay, sand, and till, with 250-ish meters of that socketed into the very strong (approaching 200 MPa UCS) limestone bedrock.” “There are a total of 87 caissons on the contract, some more than 27 meters in length. Nine were first installed on a dolphin from our barge with technical assistance from Pinnacle. This work went so well that we decided to purchase from Pinnacle the drill setup required – Down the Hole hammers and associated – and the remaining caissons were installed at the main ferry dock”, Steven explains.

“With the Steel Fist, we’ve been drilling some of the more difficult of the approximately 220 toe pins embedded 2.4 m into the bedrock.”

“We’ve been extremely happy with the performance of our equipment from Pinnacle and Robit bits. All drilling is full RC, and the process of drilling overburden – soft to hard clay and dense glacial till – from inside of the pre-driven pipe piles and locking into the ring bit at depth has not been an issue at all.

“Often, we can lock into the rings without halting rotation, very smooth, as was the drill-through process. Same for the Steel Fist, we’ve managed to drill material out from piles without rotation so as to not engage the wings and lock into the shoulder at depth, saving us significant time. We realize this is unorthodox, but it’s been working for us”, Steven says.

The CA$70M ferry dock project is still very much in progress. If everything goes as anticipated, Wolfe Islander IV, the new state-of-the-art, fully electric, zero-emission ferry – first of its kind in Canada – will start operating between the new Kingston and Wolfe Island docks in November 2023.

Read more new stories in the latest Bulletin!