POSITION AND MAIN RESPONSIBILITIES AT ROBIT

My position within Robit is as the VP for Down the Hole products (DTH). My role is to manage the strategic business area (SBA), which is focused on the Drill & Blast DTH Hammers and Bits in our offering with responsibility also for Drill Pipe, Rotary Bits along with other accessories. I am responsible for global sales growth within the SBA, focusing on key target regions, driving the ambitious growth plans for this specific business unit.

Robit has long been regarded as a supplier of quality drilling equipment, my role is to ensure Robit establishes it’s self as a truly recognized global supplier for DTH products, providing market leading products, support and drilling solutions for our customers.

I am based in the UK, but I work closely with the group head office in Tampere Region, Finland and the Perth, Australia production facility, which specializes in the manufacture of the mining Drill & Blast range of DTH equipment.

EXPERIENCE ON THE FIELD

I have been involved with DTH products for the last 10 years. My educational background was in Engineering and remains a key passion of mine. This is where I began my career in the DTH industry before moving onto other roles overseeing manufacturing operations and providing technical sales support. My experience has been hands-on in many global regions and I have been involved in applications from Drill & Blast, Geotechnical, Water Well, Construction, Oil & Gas and Reverse Circulation (RC) drilling. In more recent times, I have been responsible for the sales development of the DTH products within Robit before undertaking the new role as VP for Down the Hole products.

KEY MARKET TRENDS ON THE FIELD FOR THE NEXT FEW YEARS

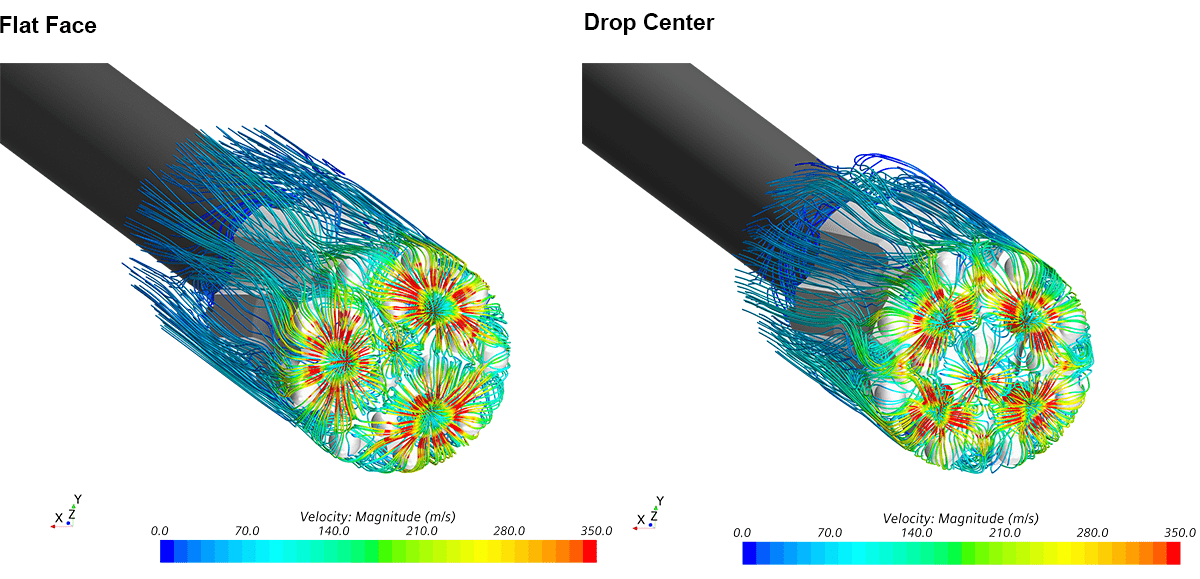

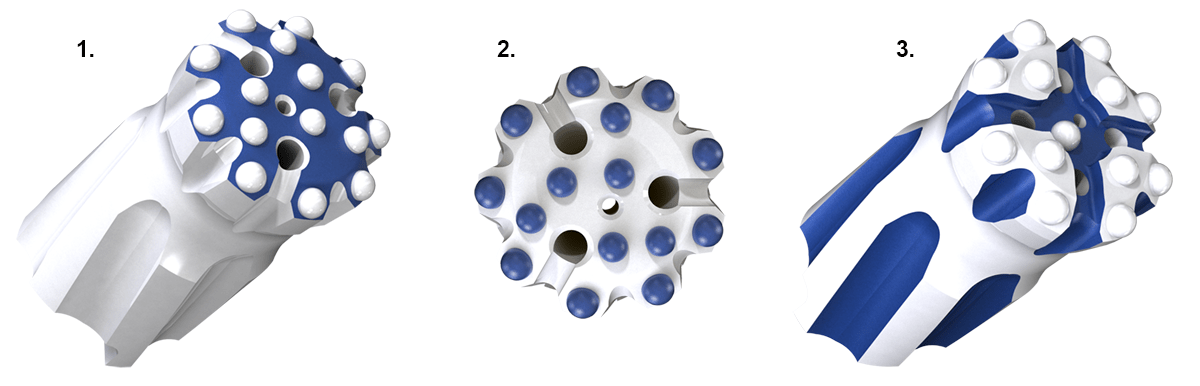

Over the next few years, reduced operational costs, improved efficiency and availability remain key for our customers and drill contractors. Robit’s commitment to continuous improvement and product development ensures we provide our customers with tools in line with their requirements. Robit’s commitment to providing the “best in class” DTH Bit will continue to reduce overall drilling costs by ensuring a longer product life. A renewed Drill Bit offering is to be released imminently, which includes additional bit sizes, face designs and bit shank choices.

New DTH Hammer product releases throughout 2021 and beyond will also improve operational efficiencies for our customers. These product releases kick-off later this year with the full release of the tubeless (footvalve-less) range, targeted at customers drilling in the most demanding applications.

HOW DO ROBIT’S ONGOING ACTIONS SUPPORT THE CUSTOMERS AND THEIR CURRENT CHALLENGES?

All product development initiatives are led by market trends or customer requirements. Furthermore, product testing and validations are carried out in conjunction with the support from our customers of which the product has been designed for. Many ongoing actions are carried out in order to support our customers with ensuring the correct availability of products globally and to ensure a consistent quality of Robit’s tools. Our complete product offering ensures we have the availability to deliver a full scope of quality drilling consumables to our customers from DTH, Top Hammer, Rotary and Drill Pipe.

Due to the COVID-19 pandemic, travel and visit restrictions have resulted in difficulties with providing face-to-face support in some regions. This has not just been limited to international travel, regional travel and visits have also been impacted. For this reason, we were quick to roll out a process of providing remote technical support in 2020 and we are extending this support offer throughout 2021 and the coming years. This has had a benefit of directly connecting end-users with the Robit technical support staff. The level of communication has been of true benefit, particularly when carrying out field trials or troubleshooting.

Further to this we have an ongoing commitment to provide DTH training and support for our distributor partners and customers. This is in the form of training modules, troubleshooting guides and service videos for the Robit DTH Equipment. Later this year we will also provide face-to-face training sessions focusing on region specific applications and equipment, all dates are yet to be confirmed due to the current travel restrictions.

HOW DO YOU SEE ROBIT IN 2021 – WHAT ARE YOUR MAIN EXPECTATIONS ON YOUR FIELD?

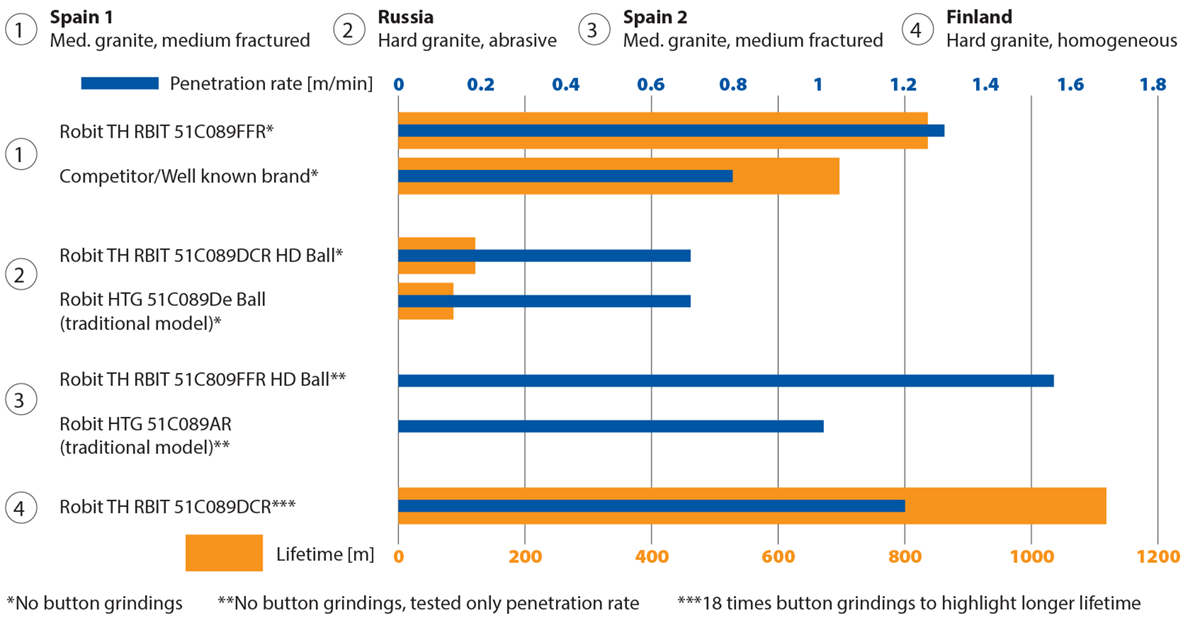

This year is an exciting time for Robit and the Down the Hole SBA in particular. The product development work that has been carried out over the last 12 months is starting to show extremely good results, increased manufacturing capacity and improved product availability actions have been put in place and we are seeing the benefits of this work already. We have many tender and testing opportunities already planned for 2021 and I am expecting a positive outcome based on our performance and success over the past six months. In recent times, our equipment has been out-performing our competition – offering increases over 30% of operational life when using Robit tools. This allows our customers and drill contractors to have a competitive cost per meter whilst receiving the quality service, support, and availability from Robit sales regions and partners. As COVID-19 pandemic travel restrictions relax, we are excited to once again meet face-to-face with our distributor partners, drill contractors and mining customers ensuring we drive the growth.

For more information: Adam Baker, firstname.lastname@robitgroup.com

Read more Robit ProTALK interviews:

- George Apostopoulos, VP Global Sales

- Jorge Leal, VP Top Hammer

- Kari Alenius, VP Finland

- Ville Pohja, VP Geotechnical

- Mikko Vuojolainen, VP North America

- Franco van Deventer, MD Southern Africa

- José Cisneros, MD Robit S.A.C.

- Steve Landreth, VP Australasia

- SK Back, Regional Sales Director – Asia

- Pavel Timofeev, VP CIS & East Europe